A 16th century lab in a 21st century lab: archaeometric study of the laboratory equipment from Oberstockstall (Kirchberg am Wagram, Austria)

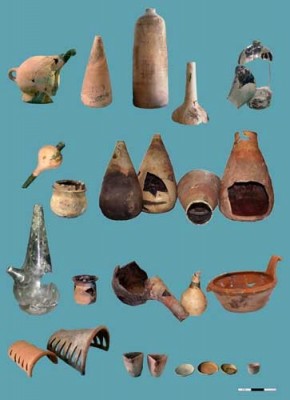

The archaeological assemblage from Oberstockstall constitutes the most comprehensive Renaissance laboratory ever recovered. The finds were discovered in a dump beneath the sacristy of the church adjoining a manor house in Kirchberg am Wagram, Lower Austria, probably buried after an earthquake. They comprise fragments of eight hundred artefacts, including triangular crucibles, shallow scorifiers, bone-ash cupels, alembics, aludels, cucurbits, adopters, receivers and other chemical apparatuses of ceramic and glass, together with metal and slag remains, furnace bricks and other artefacts of leather, textile and bone (Figure 1) (von Osten 1998; Soukup & Mayer 1997). The collection is on permanent display at the Museum Der Alchemist in Kirchberg am Wagram (http://www.tullnerfeld.at/alchemist).

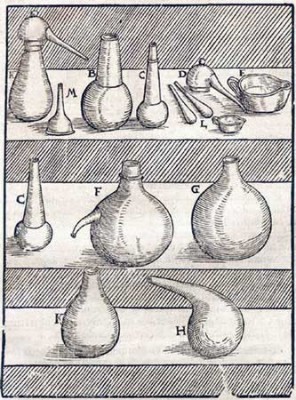

Dated to the second half of the 16th century AD, the activity in this laboratory coincides with a zenith in the quest for the philosophers' stone and the transmutation of base metals into gold, and with a major development of the techniques of metallurgical analysis in Europe. The tools recovered resemble strongly the equipment described in metallurgical and alchemical written sources of the time (Figures 2 and 3). The artefacts thoroughly illustrate with actual materials the apparatuses that used to be known only from written records and very scarce archaeological remains.

A step further in the investigation is now in progress. The archaeometric study of these remains is starting to reveal information that would otherwise remain unaccessible. A representative sample of the Oberstockstall collection is under analysis at the Wolfson Archaeological Science Laboratories of the Institute of Archaeology, University College London. The ongoing project addresses three important issues that could hardly be investigated using only written sources (Martinón-Torres forthcoming): a) the trade and supply of technical wares, b) the manufacture and technical standard of specialised ceramics, and c) the specific raw materials used and reactions carried out in a 16th century laboratory.

The first stage of the project involved non-invasive analysis of the samples as received by energy dispersive X-ray fluorescence (ED-XRF). This allowed a primary classification of the different wares and the materials processed from the contamination of the ceramics. This confirmed that the range of activities undertaken in Oberstockstall fell within the repertoire of the so-called fire assay practices. Fire assay comprises a sequence of chemical operations leading to the quantitative determination of the metals present in small samples of ores or metallurgical products. The techniques for assaying noble metals were greatly developed during the 16th century. Using different chemical operations, the gold and silver contained in a sample could be extracted and quantified. These analytical procedures were of enormous economic significance to assess the viability of a large scale metallurgical exploitation, by evaluating the richness and profitability seen in ore samples. In addition, they could be used for determining the purity of metals in coinage and jewellery. The same methods could also be seen as a tool for the extraction of quintessences, or as a test for the quality of "alchemical gold". In any case, fire assay offered a reliable analytical tool for the investigation of nature, and hinted at principles such as the conservation of mass and the constant combining proportions, which would serve as a basis for modern experimental science (Smith & Forbes 1969; Halleux 1986; Rehren 2001; Martinón-Torres 2003; Martinón-Torres forthcoming a).

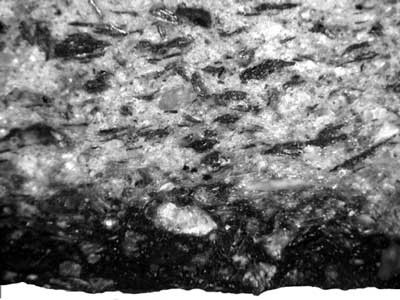

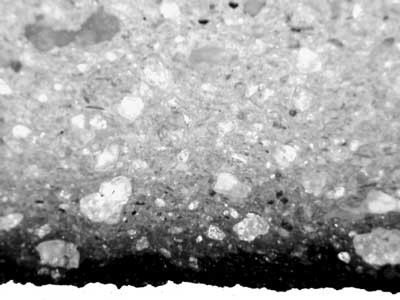

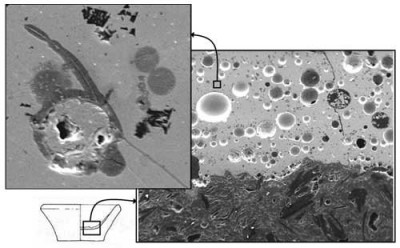

At present, the scientific analysis concentrates on the optical and energy-dispersive scanning electron microscopy (SEM-EDX) of cross-sections of the various technical ceramics. This enables a much more precise study of the ceramic material used to make and temper the different vessels, and the particular uses as evidenced in the slag remains within the artefacts (Martinón-Torres and Rehren forthcoming b).

The three hundred triangular crucibles from Oberstockstall have been a major focus of the research so far (Figure 4). These standard vessels constituted an icon of the Renaissance laboratory and indeed millions of them were traded across early modern Europe (Cotter 1992). However, little was known about their manufacture and the reasons why they were so highly esteemed. The analyses have shown that all the crucibles were made from the same highly refractory clay, which is different from that used for all other artefacts. This clay was mixed with varying amounts of sand, grog and/or crushed graphite, which improved the resistance of the vessels to the thermal and mechanical stresses of the assay operations. In particular, those tempered with graphite would also be better heat conductors and more resistant to chemical attack. The provenance of these specialised wares will be tested by comparing the microstructure and composition of the Oberstockstall crucibles to samples of contemporaneous crucibles, graphite and clay recently collected from Obernzell (Germany), a well-known producer of graphitic crucibles in the Renaissance. Finally, a particularly striking feature of these crucibles is their external appearance. As can be seen in the unused ones, these vessels were deliberately fired in a very smoky potter's kiln that left a lustrous, black soot on their surface. As a result, all crucibles would look the same when purchased, irrespective of their specific composition and quality (Figures 5 and 6).

Another artefact type frequent in the assemblage (approx. 40 units) is the scorifier (Figure 7). These shallow ceramic plates were used for a range of intermediate reactions, such as the oxidation of lead bullion in order to concentrate the noble metals contained in it (Figure 8), or the primary melting of a sample prior to further refining, a fluxing process in order to separate the gangue from the ore. These operations would generally be technically less demanding and require relatively lower temperatures. Accordingly, in stark contrast with the standardised crucibles, the scorifiers show a wider variability in composition and microstructure. They are often less refractory than the crucibles, and their differing compositions indicate a more opportunistic supply in the clays used to make them. Significantly, the only graphite-tempered scorifier identified so far contained slag remains with traces of copper which, having a relatively high melting point, would have required an especially refractory vessel (Figure 8). It seems, therefore, that the experience gained through the experiments allowed a careful maximisation of resources in economic terms.

Lastly, the remains include some sixty bone-ash cupels (Figure 10). These were very specialised vessels for the refining of noble metals. In a sophisticated process, the bone-ash material absorbed by capilarity the oxidised base metals such as lead and copper, leaving on the surface a regulus formed by the noble metals. The difficulties entailed by making bone-ash cupels were acknowledged by Renaissance writers, who provided detailed guidelines on how to make them. In Oberstockstall, a big lump of bone-ash was found, indicating that the artisans themselves would have probably made their own cupels. Some of these cupels have shown high concentrations of bismuth, perhaps documenting early attempts to identify the nature of this 'new' metal as different from lead (Rehren 1998).

Once the examination of the artefacts themselves is completed, the analysis will concentrate on the traces of use and their relationship with the different tools, hoping to provide more specific details as to the raw materials and recipes used. At its current stage, this project already is yielding valuable information regarding the degree of technical knowledge of Renaissance assayers, their perception of different materials and their understanding of natural elements, as well as particulars of the manufacture and supply of specialised tools for chemical operations. This allows a study of the interplay of early metallurgy and alchemy while providing real data that may help decipher the recipes given in the often obscure texts written by Renaissance alchemists. Scientific archaeology is proving to be a useful, as yet little exploited, complementary approach to the history of science.

Acknowledgements

The authors are grateful to the Salomon family and the Museum der Alchemist in Oberstockstall for kindly allowing the study and sampling of their collection, and to Rudolf Hammel, former major of Obernzell, for providing comparative material on behalf of the Keramikmuseum. Many thanks are also due to Bill Sillar for his always enlightening suggestions, to Kevin Reeves for technical support during SEM-EDX analyses, and to Stuart Laidlaw for advice in image processing. Financial assistance by the Dixon Studentship of the University of London, Área Sociocultural Caixanova, Arts and Humanities Research Board, Institute of Archaeology UCL Awards, Central Research Fund of the Academic Trust Funds Committee, University of London, and Graduate School UCL, is thankfully acknowledged.

References

- COTTER, J. P. 1992. 'The Mystery of the Hessian Wares': Post-medieval Triangular Crucibles, in D. Gaimster & M. Redknap (eds), Everyday and Exotic Pottery from Europe c. 650-1900: 256-272. Oxford: Oxbow.

- HALLEUX, R. 1986. L'alchimiste et l'essayeur, in C. Meinel (ed), Die Alchemie in der Europäischen Kultur- und Wissenschaftsgeschichte: 277-291. Wiesbaden: Herzog August Bibliothek in Kommission bei Otto Harrassowitz.

- MARTINÓN-TORRES, M. 2003. Química en arqueología y la arqueología de la química: el ensayo. Gallaecia 22.

- MARTINÓN-TORRES, M. forthcoming. For an Archaeology of Alchemy and Chemistry. Ambix. The Journal of the Society for the History of Alchemy and Chemistry.

- MARTINÓN-TORRES, M. & Th. REHREN. forthcoming a. Alchemy, Chemistry or Metallurgy? All of them. Fire Assay in Renaissance Europe. Der Anschnitt.

- MARTINÓN-TORRES, M. & Th. REHREN. forthcoming b. Ceramic Materials in Fire Assay Practices: A Case Study from 16th-Century Laboratory Equipment, in Proceedings of the 7th European Meeting on Ancient Ceramics (EMAC), Lisbon, 27-31 October 2003.

- REHREN, Th. 1998. Kontext und Analyse der Aschkupellen von Oberstockstall, in S. von Osten, Das Alchemistenlaboratorium von Oberstockstall. Ein Fundkomplex des 16. Jahrhunderts aus Niederösterreich: 333-348. Innsbruck: Universitätsverlag Wagner.

- REHREN, Th. 2001. Ores, Crucibles and Cupels: Past and Present Possibilities of Scientific Analysis. Cahiers d'archéologie du CELAT 10: 65-71.

- SISCO, A. G. & C. S. SMITH (eds). 1951. Lazarus Ercker's Treatise on Ores and Assaying, Translated from the German Edition of 1580. Chicago: The University of Chicago Press.

- SMITH, C. S. & R. J. FORBES. 1969. Metallurgy and Assaying, in C. Singer, E. J. Holmyard, A. R. Hall & T. I. Williams (eds), A History of Technology, vol. 3: From the Renaissance to the Industrial Revolution, c. 1500-c. 1750 (rep. edn; 1st. edn. 1957). Oxford: Clarendon Press.

- SOUKUP, R. W. & H. MAYER. 1997. Alchemistisches Gold. Paracelsistische Pharmaka. Laboratoriumstechnik im 16. Jahrhundert. Wien: Böhlau.

- VON OSTEN, S. 1998. Das Alchemistenlaboratorium von Oberstockstall. Ein Fundkomplex des 16. Jahrhunderts aus Niederösterreich. Innsbruck: Universitätsverlag Wagner.

Authors

- Marcos Martinón-Torres

Institute of Archaeology, University College London, 31-34 Gordon Square, London WC1H 0PY, United Kingdom (Email: m.martinon-torres@ucl.ac.uk) - Thilo Rehren

Institute of Archaeology, University College London, 31-34 Gordon Square, London WC1H 0PY, United Kingdom (Email: th.rehren@ucl.ac.uk) - Sigrid von Osten

Oberstockstall 46, A-3470 Kirchberg am Wagram, Austria

Cite this article

Cite this article